The Critical Role of Quality Assurance in Recycled Plastic Supply Chai…

페이지 정보

본문

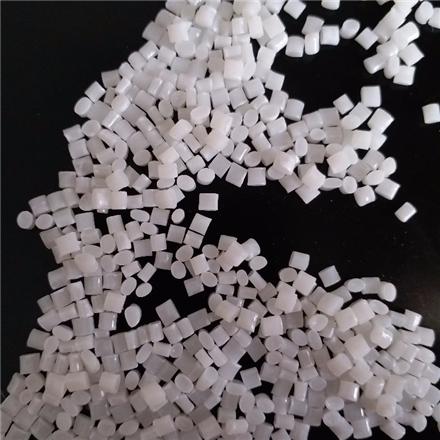

Quality assurance acts as a vital safeguard in ensuring that plastic recycling networks deliver safe, consistent, and reliable materials to industrial processors and brand owners. Unlike virgin plastic, reprocessed plastic flakes can differ markedly in molecular structure, shade, contamination levels, and durability due to the complex origins in municipal and commercial waste streams. Failure to implement strict QA protocols these inconsistencies can lead to product failures, safety hazards, تولید کننده گرانول بازیافتی and loss of consumer trust.

The initial phase of QA is accurate categorization and separation of plastic streams. Different types of plastics such as thermoplastics like PET, HDPE, PP have unique thermal thresholds and reactivity profiles. Inclusion of non-plastic debris—like metals, glass, or nonrecyclable plastics—can render the material unsuitable for high-value applications. Optical and sensor-based separation tools, supplemented by human verification, help guarantee that homogenous polymer batches proceed to processing.

Once sorted, the plastic is subjected to thorough washing and refining. Process monitors verify rinse cycles, dehydration levels, and contaminant removal rates to eliminate grime, ink, glue, and organic residues. Even trace impurities can degrade the mechanical and aesthetic qualities of final products, such as food packaging or automotive parts.

Scientific analysis forms a critical pillar. Post-consumer plastic fragments are evaluated using MFI, ASTM tensile, Charpy impact, and FTIR spectroscopy to ensure alignment with regulatory benchmarks and end-use demands. Accreditations such as RCS, GRS, or UL ECVP provide independent proof of authenticity, traceability, and ethical sourcing.

Digital provenance is indispensable. Cloud-based logistics software help document the origin of the plastic waste, the processing steps it underwent, and the final destination of the recycled material. This visibility strengthens confidence among retailers and end users who want to ensure their sustainability claims are legitimate.

Quality assurance must be continuous but an dynamic system. As recycling technologies evolve and new types of plastic waste enter the system, criteria need continuous refinement. Regular audits, employee training, and collaborative improvement channels help maintain high quality over time.

As global sustainability goals intensify, quality assurance is what turns the promise of recycling into a reliable reality. It ensures that post-consumer resin isn’t merely a marketing term—it’s a high-performance polymer rivaling or exceeding new resin while minimizing carbon footprint. Neglecting rigorous controls the the global plastic recovery network faces collapse in consumer and regulatory trust.

- 이전글The Advantages of Continuous Extrusion for Uniform Granules 25.12.22

- 다음글The Impact of Processing Temperature on Polymer Degradation 25.12.22

댓글목록

등록된 댓글이 없습니다.